Building a Cleaner Future with THE NATIONAL Academy of Sciences of Ukraine

In strategic collaboration with the Gas Institute of the National Academy of Sciences of Ukraine (Depar tment of Alternative Fuels), we co-develop and deploy waste-to-energy solutions—transforming plastics, rubber, and carbon composites into gasoline, natural gas, electricity, and propane.

FEATURES

1

Energy Resource Production

We don’t just recycle; we transform waste into valuable energy resources. From gasoline and fuel oil to electricity and synthetic gas blends, our methods harness the potential of discarded materials—giving you clean, reliable power while keeping plastics, rubber, and carbon composites out of landfills.

2

Comprehensive Waste Diversion

We tackle the toughest streams—non-biodegradable plastics, scrap tires, ocean plastics, and carbon fiber from retired wind-turbine blades—diverting them from landfills and waterways. By turning global waste challenges into energy solutions, we reduce pollution and preserve natural resources.

3

Advanced Technology

Our state-of-the-art gasification, pyrolysis, and plasma systems break down complex waste into clean energy with maximum efficiency. These cutting-edge processes unlock high yields of liquid and gaseous fuels while keeping emissions—and environmental impact—low.

4

Closed-Loop, Carbon Neutral Process

Every output and by-product is captured, recycled, and fed back into our operations—slashing CO₂ emissions to near-zero. Beyond titanium oxide, we recover high-purity activated carbon for filter media production and glass wool insulation for the construction industry. By turning waste tires, plastics, and carbon composites into energy and these valuable materials, we close the loop on resource use and keep greenhouse gases out of the atmosphere.

5

Expert Team

Our cross-disciplinary team—engineers, chemists, environmental scientists, and operations specialists—brings decades of hands-on experience. We combine deep technical know-how with a passion for sustainability to deliver turnkey solutions that really work.

About Energy Science Corporation

At Energy Science Corporation, we envision a world where waste isn’t wasted—where the materials that “never go away” become tomorrow’s clean energy. As pioneers in sustainable technology, we transform hard-to-recycle plastics, rubber, carbon foams, and other non-biodegradable materials into high-value energy products: from gasoline and diesel-grade oil to electricity and synthetic gas blends.

Our Mission

- Clean the Planet: We tackle the global challenge of mounting waste by diverting it from landfills and waterways.

- Produce Reliable Energy: We employ advanced gasification, pyrolysis, and plasma technologies to unlock the energy trapped in waste streams.

- Protect Future Generations: Every ton of material we process reduces pollution, conserves natural resources, and cuts greenhouse-gas emissions.

Our Core Values, Innovation, Integrity, Collaboration

- Innovation: Continually pushing the boundaries of waste-to-energy technology.

- Integrity: Upholding the highest ethical and environmental standards.

- Collaboration: Partnering with communities, industry, and academia to drive real impact.

Why We’re Different

Innovative Science

In addition to recovering liquid and gaseous energy fractions, our processes extract titanium oxide byproduct—an otherwise discarded material—which we capture, purify, and recycle as a valuable industrial feedstock.

Closed-Loop Process

Our fully integrated system recycles every output and byproduct back into production, maximizing resource use and minimizing CO₂ emissions to near-net-zero levels.

Full-Cycle Responsibility

From feedstock collection through end-use power generation, we maintain cradle-to-grave accountability.

Partnership-Driven

We collaborate with municipalities, industrial partners, and environmental agencies to scale solutions that make a real impact.

Join us in powering a cleaner, greener tomorrow—where waste becomes opportunity, and sustainability drives progress.

Our Projects & Operational Plants

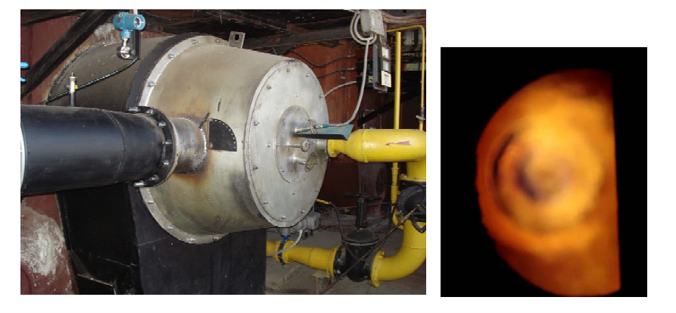

Start of research: laboratory stand for gasification of rubber crumbs and wood waste. Developed according to our drawings, and a cogeneration machine powered by synthetic gas.

The tested solutions, including gas purification, a cooling unit, and utilization of thermal energy from the gasifier, were implemented at a paper mill in Malyn city, Ukraine. (2013-2015 years)

Part 1

What we have already done. Our technological prototypes have been successfully tested at operating industrial enterprises.

Examples of existing waste processing and energy production facilities (developed by us)

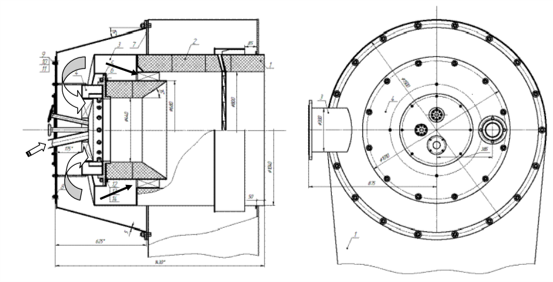

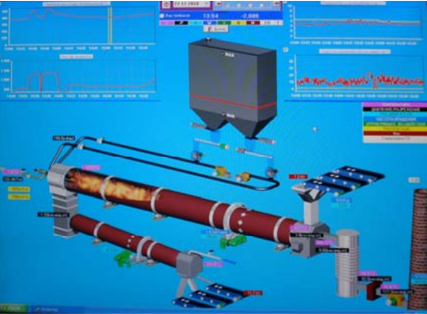

The existing 1 MW gas power plant (designed according to our drawings and under our scientific guidance) is an operational complex.

It has been operating in Netishyn city, Ukraine, since 2020 (running on rubber crumbs and wood waste), producing heat and electricity, charcoal, and non-activated coal.

The technical solutions developed allow for the construction of modules with a capacity of 4 MW of electrical energy and 4 MW of thermal energy. The consumption of rubber crumbs is 3.9 tons per hour, and carbon production is 1.9 tons per hour.

What we have already done.

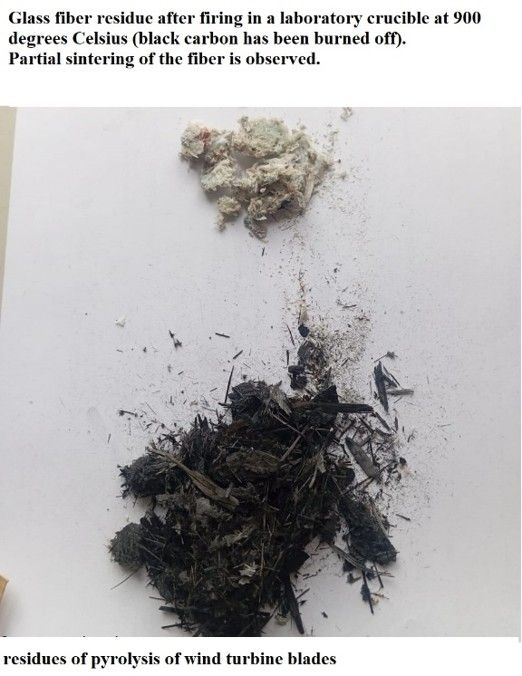

We have begun research into the pyrolysis of wind turbine blades and the recycling of fiberglass.

A number of tests were conducted, several tests were made on the pyrolysis of plastic from wind turbine blades. The photo shows the remnants of fiberglass after pyrolysis (black), and after firing at 900 degrees Celsius (you can see that the carbon has burned out and the fiberglass itself has become light in color). Further work is being done to obtain pure fiberglass for sale as a finished raw material.

Start of research in 2025: laboratory stand for pyrolysis of plastic and rubber crumbs. Objective: to develop technical solutions for pyrolysis with the production of chemicals suitable for further processing. No waste in the processing process. Solutions for the pyrolysis of wind turbine blades and the production of commercial recycled glass fiber suitable for reuse.

What can be obtained from recycling wind turbine blades

composition of plastic pyrolysis (by input raw materials):

- Liquid fraction – 192kg (synthetic oil)

2. solid fraction – glass fiber 480 kg (as a raw material for filling concrete, asphalt)

3. solid fraction – carbon 86 kg

4. TiO2 ~ 10 / kg (according to open source scientific research)

5. Gaseous fraction – 232kg (m3)- (use in technology that saves purchased fuel for heating the installation)

An existing plant in the Republic of Poland.

In 2022, the construction of a plant with a tire processing capacity of 60,000 tons per year will begin

The plant is profitable and its technology meets all EU environmental standards.

Key Benefits

- Autonomous Energy Supply

Power, heating and cooling for data centers anywhere in the U.S.—only raw-material delivery and road access required. - Carbon Emissions Reduction

Synthetic gas replaces natural gas or coal, slashing CO₂ output. - 100% Waste Valorization

Full recycling of tires and plastics into:

– Liquid fuels & syngas for CHP

– Activated carbon, rubber crumb, glass wool, titanium oxide

– Reclaimed metal cord as scrap - Circular-Economy Model

All outputs and by-products are fed back into production or sold into domestic markets.

Technical Highlights

- Feedstock Capacity: 205 tons/hour of tires & plastics

- Energy Generation: 2 × 250 MW synthetic-gas CHP units (electric)

- Cooling System: Heat-to-cold unit for data-center HVAC

- By-products:

– 850 kg rubber crumb & 150 kg steel cord per ton of tires

– ~700 m³ syngas per ton of feedstock

– Activated carbon & glass wool insulation

– Titanium oxide recovery

Economic Highlights

- CapEx: USD 1,815 million

- Annual Revenue: USD 376 million

- Payback Period: ≈ 5 years

Process Flow

- Shredding & Sorting: Tires and plastics → uniform feedstock

- Gasification & Pyrolysis: High-temperature conversion → syngas + char + oils

- Energy Recovery: Syngas → steam boiler & turbine → electricity; steam → cooling

- By-product Refining:

- Char → activated carbon for filters

- Glass fiber feedstock → glass wool insulation

- Steel cord → recycled scrap

- Residual titanium oxide → industrial feedstock

LEADERSHIP

Igor Glukh is the President & CEO of Energy Science Corporation (ESC).

He brings 20+ years of executive leadership in energy and utilities: GTM strategy, product-market fit, industrial scale-up, P&L ownership, plant launch & operations, and end-to-end supply chains and procurement. He led international expansion across the CIS, Africa, and Europe, driving market-share growth for a new brand from ≈2% to ≈89% in 1 year. Experience with the World Bank’s UDHEEP (Ukraine District Heating Energy Efficiency Project) includes procurement under WB rules, technical scoping, coordination of municipal utilities and suppliers, and energy-efficiency KPI tracking. His international background spans energy-resource production in Ukraine and supply operations to and from Ukraine, Belarus, and Russia, as well as several African countries (including Angola and Burundi), with a focus on compliance, risk management and stakeholder engagement. Political activity in Ukraine (1999–2010): Administration of the President of Ukraine and Kyiv City Hall.

Yevhen Mahlyovannyi — Vice President, Financial & Economic Strategy

Profile:

Energy policy and district-heating expert with 20+ years of experience across regulation, tariff design, and municipal heat-system modernization. Former commissioner at Ukraine’s National Energy and Utilities Regulatory Commission, where he led improvements to heat/water tariff methodologies (incl. RAB regulation) and investment-program procedures. Advises government and donors on heat-sector reform, led USAID-supported work on Lviv’s Heat Supply Scheme, and launched pilots to integrate geothermal technologies into district heating. Contributed to the legislative framework for the National Electronic Energy Monitoring System (NEMIS) under a UNDP-GEF project. Education in construction engineering and public administration.

Expertise: tariff design & regulation; district-heating modernization; geothermal integration; EMIS/NEMIS policy; waste-to-energy feasibility; public-sector energy efficiency.

Selected highlights: NEURC working group on Rules for Thermal Energy Use; USAID Lviv heat-scheme baseline & RES measures; Ministry support on heat-tariff digitalization.

Kostyantyn Pyanykh, D.Sc. — Vice President, R&D, Technology & Financial Planning

Profile :

Doctor of Technical Sciences and Head of the Alternative Fuel Technologies Department at the Gas Institute of the National Academy of Sciences of Ukraine, with 29 years in industrial heat & power. Recognized with Ukraine’s 2020 State Prize in Science & Technology, author of 100+ publications and 12 patents. Led large-scale industrial conversions from natural gas to biofuels (sunflower husk, sawdust, peat) at ArcelorMittal Kryvyi Rih, Ferrexpo, and other plants; professor at Kyiv Polytechnic Institute; managed USAID-backed city heat-planning and audit projects. Core R&D includes gasification and alternative gaseous fuels for industry.

Expertise: gasification & alternative gaseous fuels; biofuel substitution in rotary kilns; industrial decarbonization; WtE processes; project commercialization & commissioning.

Selected projects:

ArcelorMittal limestone-kiln biofuel conversion; Ferrexpo pellet-kiln conversions; Lubomir kiln (2017, 2023); Kropyvnytsky heat-supply scheme; Slavutych system energy audit.

Delivering clean energy to communities and data centers, closing the waste loop, and powering a sustainable tomorrow—wherever they are.

Let's talk!

Contact Us

Please try again later.

Business Hours

- Mon - Fri

- -

- Sat - Sun

- Closed